Biomass top loader for boiler feed

Al Industrie has created its AA Biomasse brand to offer a complete biomass storage and conveying solution with an AA Biomasse Toploader and an AA Biomasse [...].

AL Industrie is launching its AA Biomasse brand to offer a complete biomass storage and conveying solution, including the AA Biomasse Toploader and an AL Industrie modular conveyor. This solution is designed to efficiently manage a variety of materials such as wood chips, RDF, B-wood and other waste, with full automation enabling very large volumes to be stored without the need for complex civil engineering.

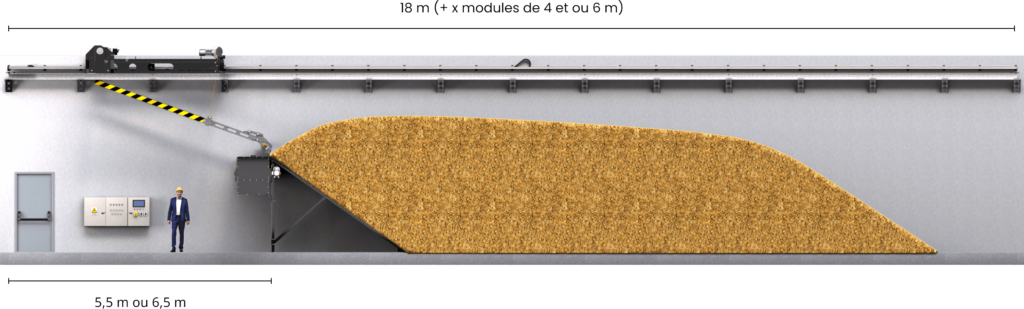

The Toploader, manufactured entirely in France, offers up to 600 m³ of storage capacity, a distribution rate of up to 60 m³/h and can be installed in less than a week. It is particularly well-suited to industrial boiler rooms and renewable energy processes.

How the Toploader works

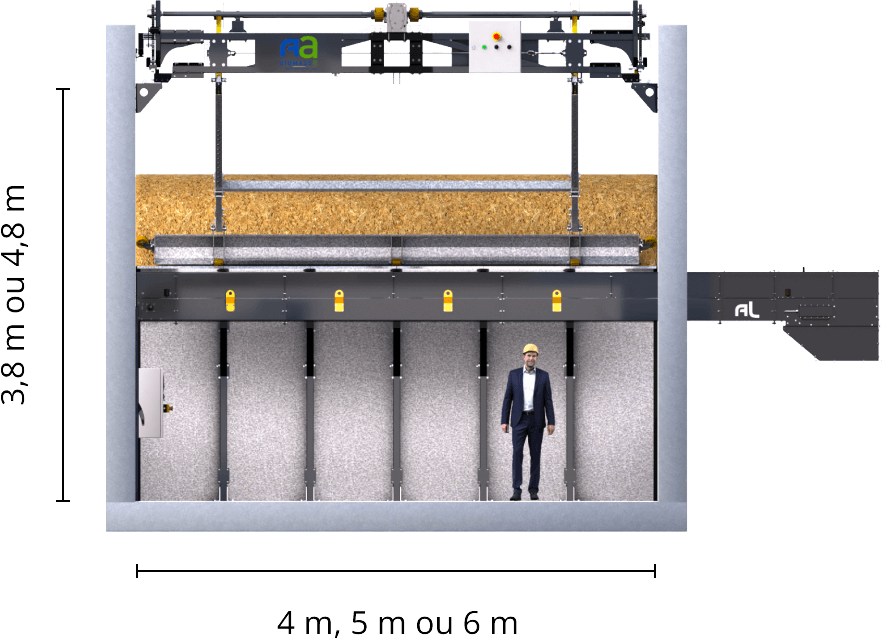

The Toploader feeds a biomass boiler by providing both storage and conveying. A lorry unloads the material into the storage area, then the operator activates the translation carriage. Travelling on rails between two walls, it moves the material to form a uniform pile.

When the boiler signals the need for replenishment, the Toploader switches to conveying mode. The trolley's shovel collects the material and dumps it into the modular conveyor, which then distributes it to the boiler.

The top-of-the-range modular conveyor is fully adaptable, with a metallised belt and standardised modules. It can be configured to any shape and size required to efficiently feed any renewable energy production process.

The Toploader is available in several configurations in terms of width, rail height and length, ranging from 18 to 50 metres.

Discover our online configurator on our new website www.aa-biomasse.com to customise your Toploader. We also offer hopper, hopper bottom and conveyor solutions for biomass.

AA Biomasse: the brand specialising in the storage and logistics of your biomass.