Motorised rotating chute

Our client produces parts for the automotive industry and parts manufacturers. It therefore works with a large number of [...]

Issues

Our customer, who specialises in the production of parts for the automotive and component industries, uses a large number of machines, particularly for stamping. They needed a new chute to fill containers with their sheet metal off-cuts.

Solution

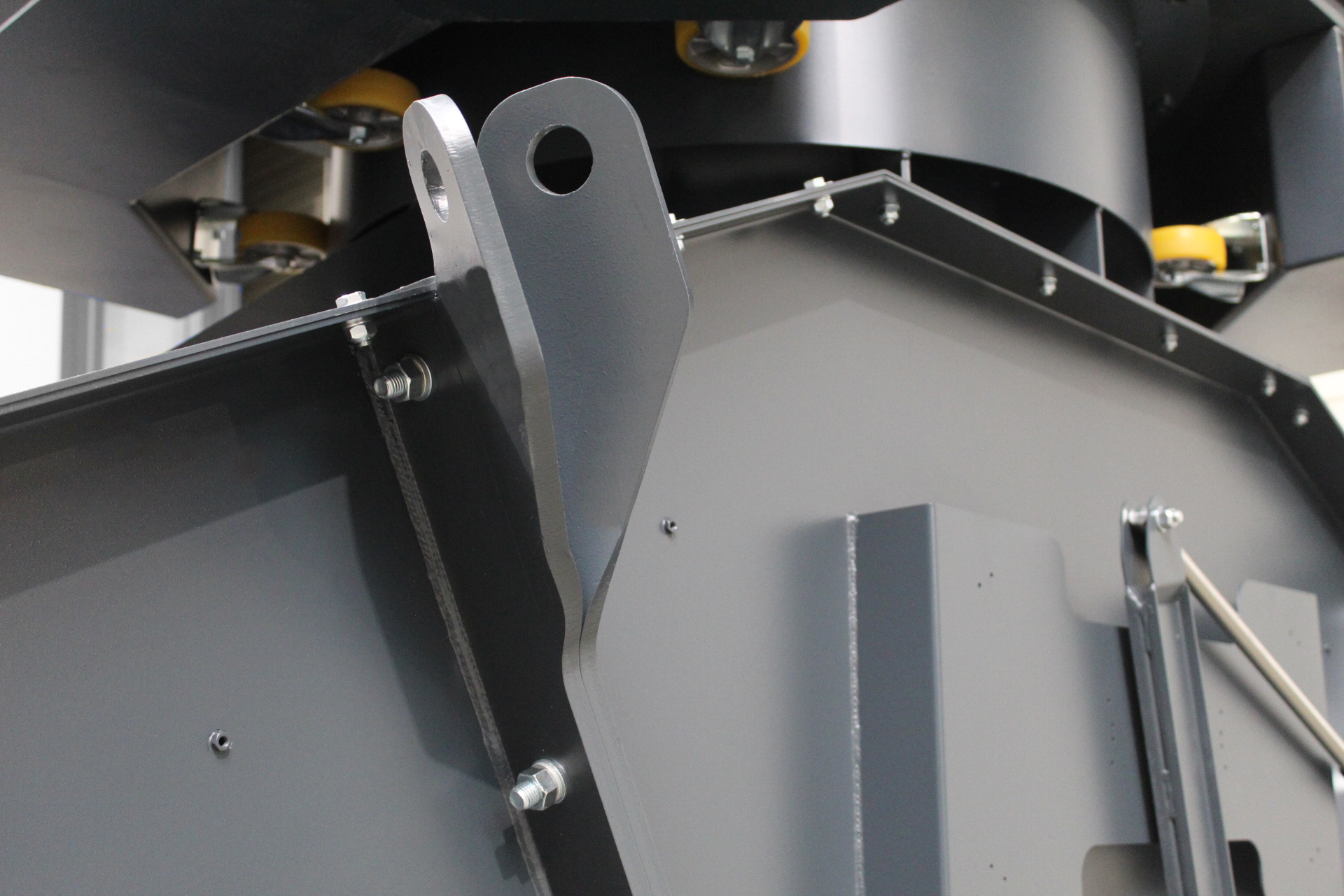

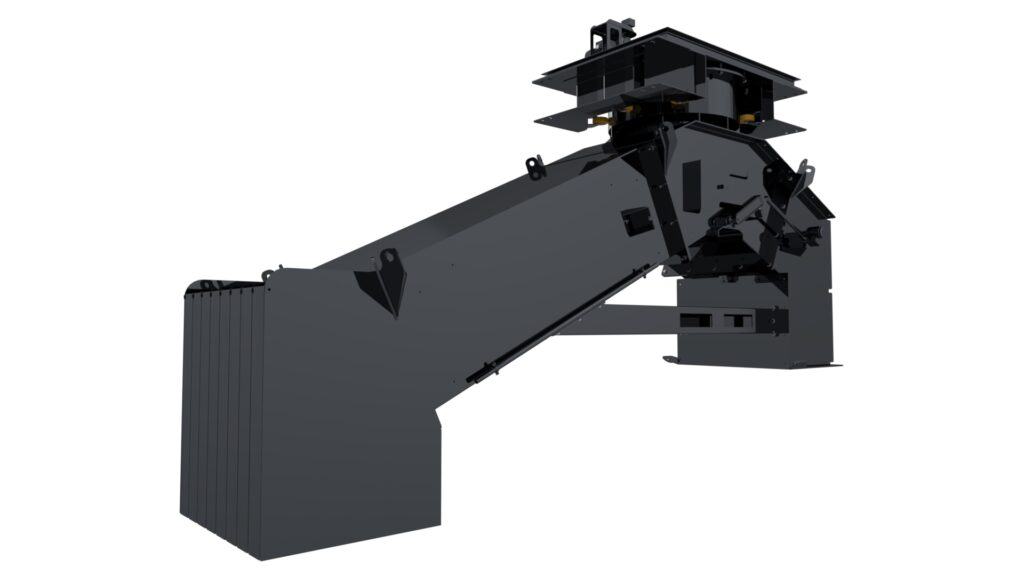

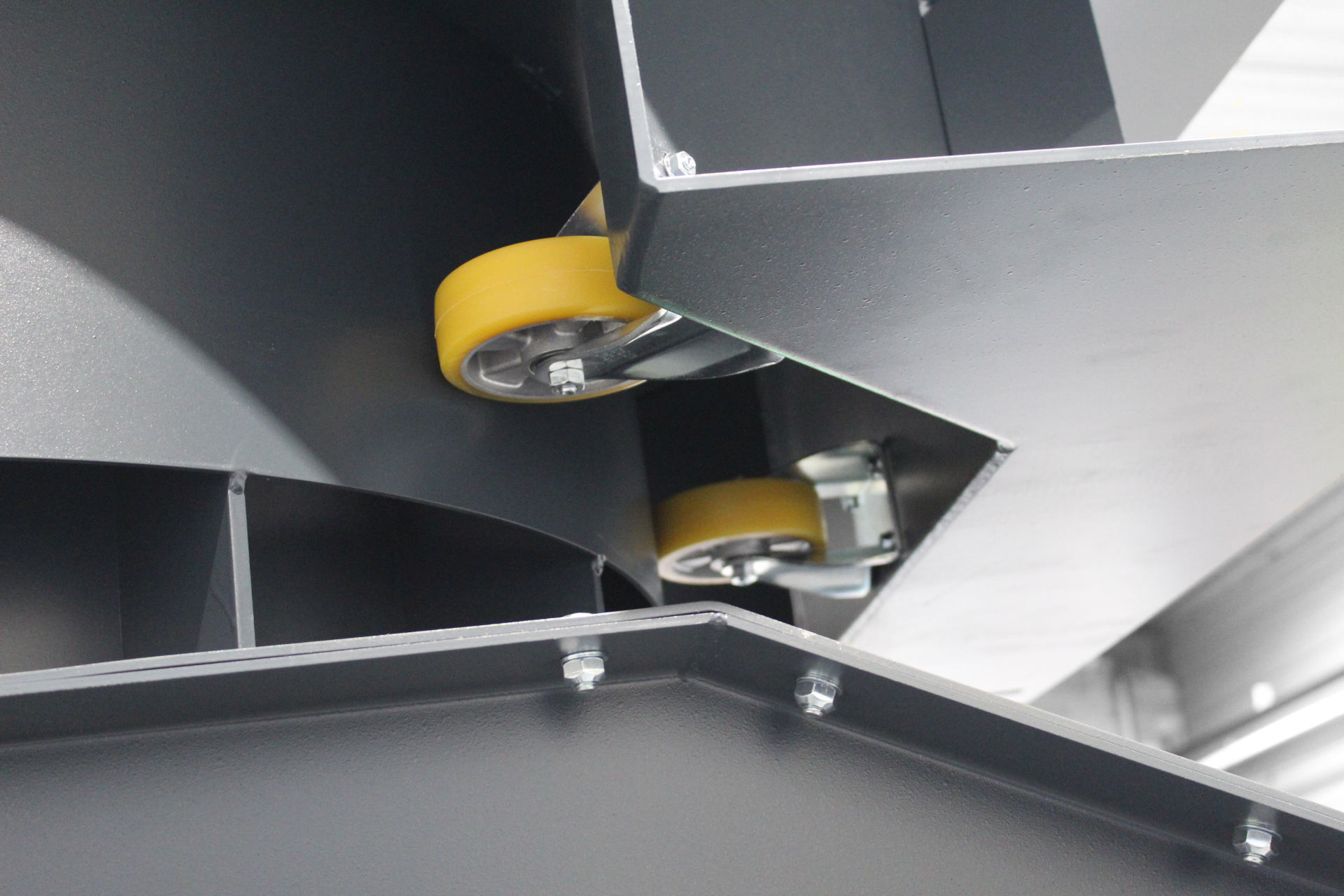

The AA Biomasse teams designed a motorised rotating chute capable of turning 360 degrees. The motor at the top of the chute is connected to two gears that enable rotation. To ensure better rotation and avoid steel-on-steel friction, an agricultural undercarriage has been added. The chute is also equipped with an electric actuator that controls the opening of the central hatch, allowing the user to choose which side the material will fall through. A metal curtain slows down the fall, giving greater control over the position at which the waste arrives.

The chute is placed at the exit of the conveyor to collect the sheet metal scraps. Thanks to the encoder and the filling sensors, it discharges the off-cuts into the container in a balanced manner, with different unloading positions.

Do you have a waste conveying project, a motorised rotary chute or would you like more information about our conveying solutions? Contact our sales representatives.

Wear-resistant steel inner lining

Offset compensating wheels

Agricultural undercarriage

Encoder

Filling sensors