Conveyor for wooden pallet shredder

Wood pallet shredder conveyor In this case, the shredded wood chips come from an SPE 1300 shredder, where pallets are inserted into a conveyor [...].

Context

Shredded wood chips come from an SPE 1300 shredder, where pallets are inserted to produce logs and heating pellets.

Challenge

The customer wanted to transport chipped wood chips as well as nails and staples from the pallets. The main challenge was to separate the wood chips from the metal materials.

Solution

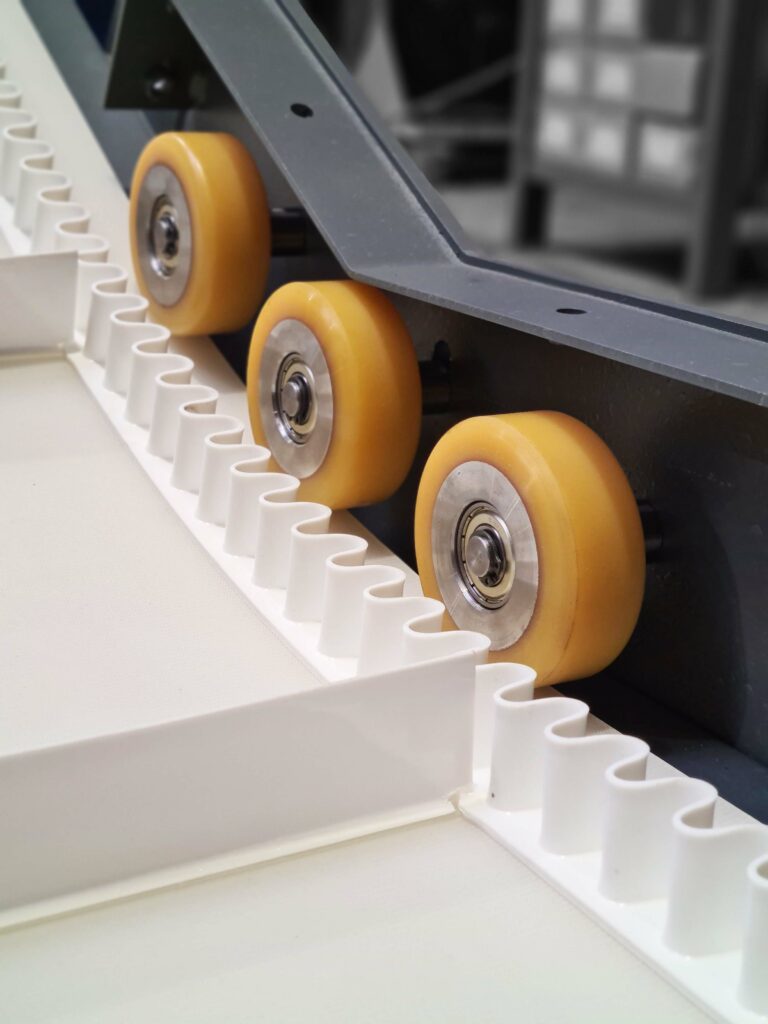

AA Biomasse designed a watertight polyurethane belt conveyor to meet this need. Positioned under the SPE 1300 shredder, this conveyor receives the shredded wood chips. It is equipped with a magnetic drum to extract nails and staples. A separator chute then separates the shredded wood chips from the metal materials.

Operation

The SPE 1300 shredder crushes the pallets, and the shavings are discharged onto the polyurethane conveyor belt. The magnetic drum lifts up the nails and staples, which are then separated from the shavings by a chute. Two skips under the chute collect the separated materials: one for the crushed wood chips and the other for the nails and staples. The shredded chips are then processed and reused.

Do you have a waste evacuation or chip transport project, or would you like more information about our conveyor solutions? Contact our sales representatives.

2-ply polyurethane strip, 4 mm thick

Screw jack

Magnetic drum

Side panels on feeder

Separating chute

Tubular feet

Geared motor with integrated torque limiter