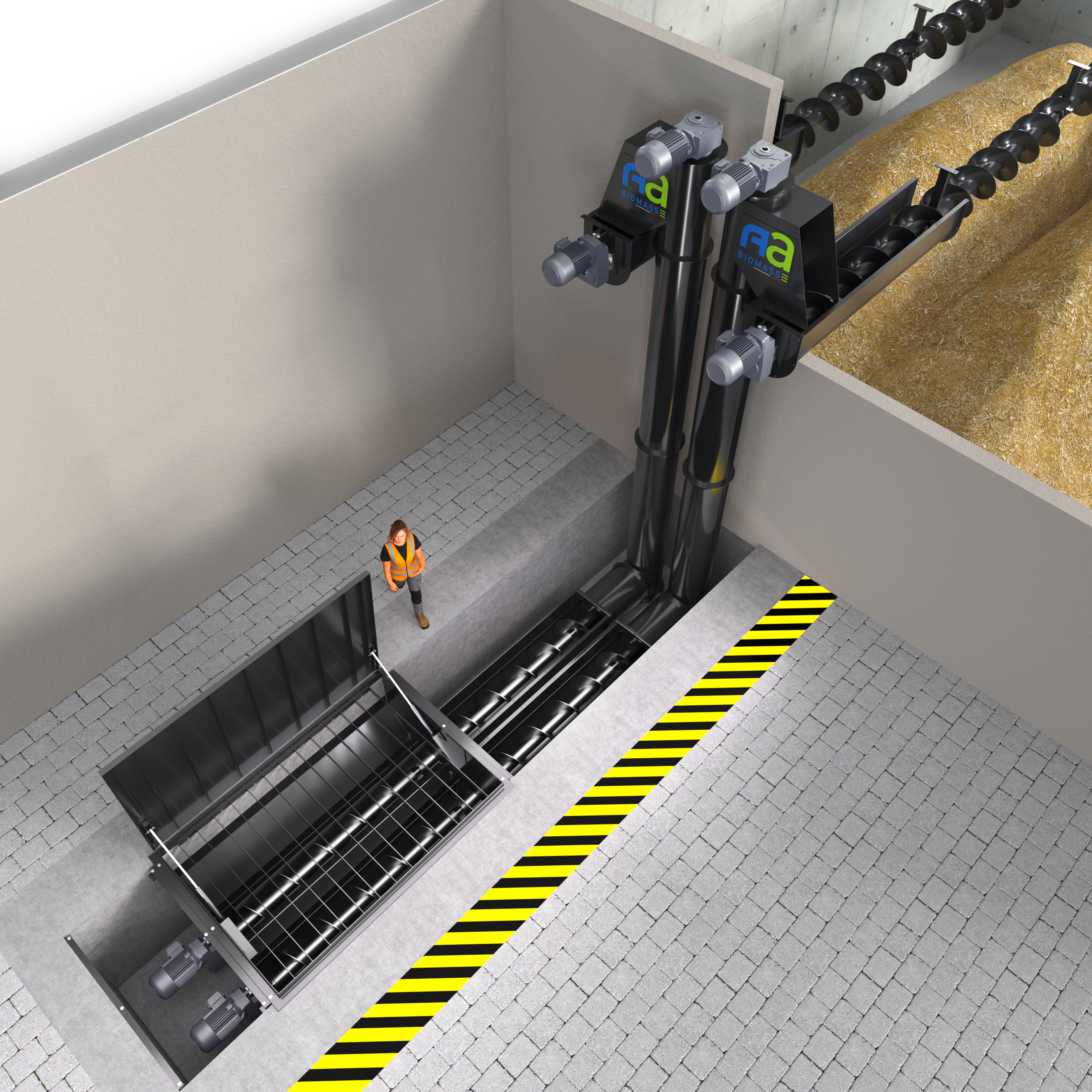

TD200 biomass unloading hopper with a capacity of 200 m3/h

Biomass unloading hopper with a discharge capacity of 200 m³/h

Screw Unloading Hopper for Biomass — Throughput and Efficiency

Our screw unloading hopper system allows for quick and safe unloading of trucks directly into the facility. The biomass is then transported by a vertical screw conveyor to a silo or storage area, where two horizontal screws ensure even distribution of the material.

Visible and Key Features:

Robust hopper with a secure opening for truck unloading, equipped with a foreign body screen.

Integrated screw conveyor that transports biomass vertically without clogging.

Even distribution in the silo thanks to the horizontal screws that spread the material.

Modular capacity: a 100 m³/h hopper can be combined with one or two others to reach up to 300 m³/h.

Adjustable throughput: from 100 to 300 m³/h depending on the number of hoppers and the configuration.

System Advantages:

Rapid truck unloading, reducing waiting times and interruptions.

Efficient transport of large volumes, even at high throughput.

Even distribution for continuous feeding of silos or production lines.

Modularity and flexibility to adapt to the specific needs of the industrial site.

Safety and robustness suited to demanding environments.

The system shown in the photo features a double hopper, equipped with two vertical screw conveyors and a secure gate, perfectly illustrating the modular design and reliability of the installation.