Wood and biomass conveyor Flow rate 10 m3/h

Ideal for conveying all your types of Biomass. Wood chips, granules, pellets, wood waste, b wood but also CSR and many others.

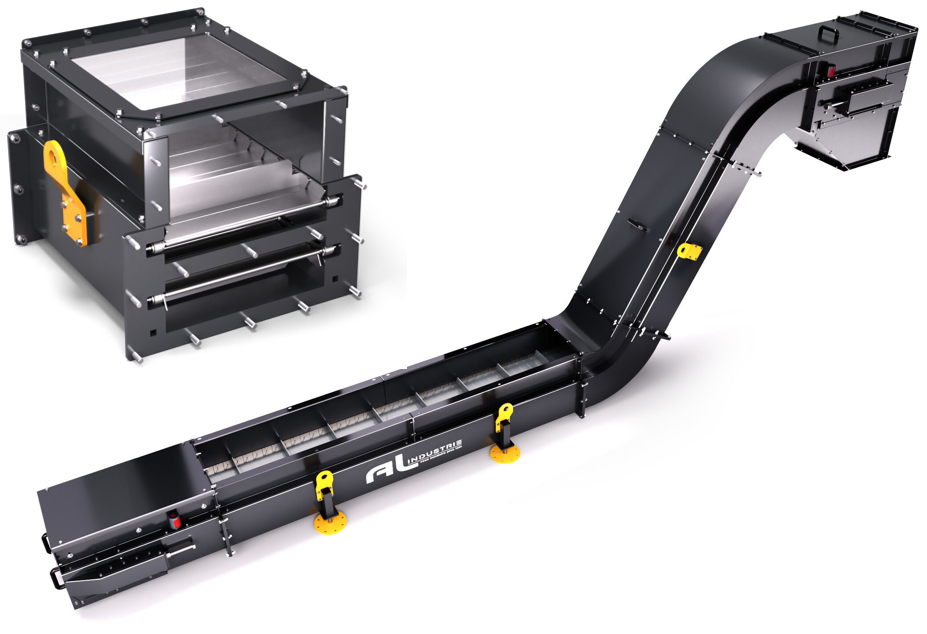

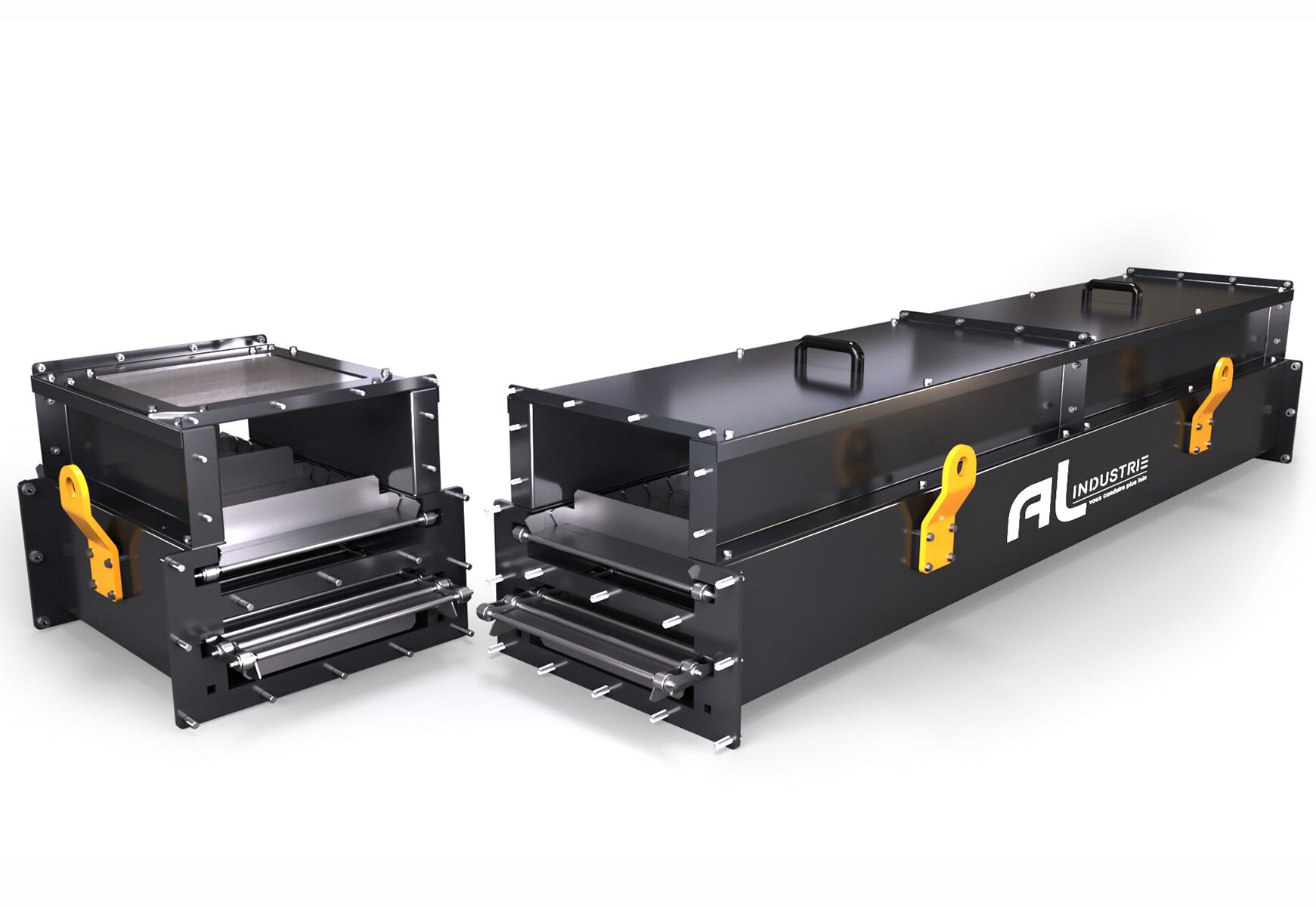

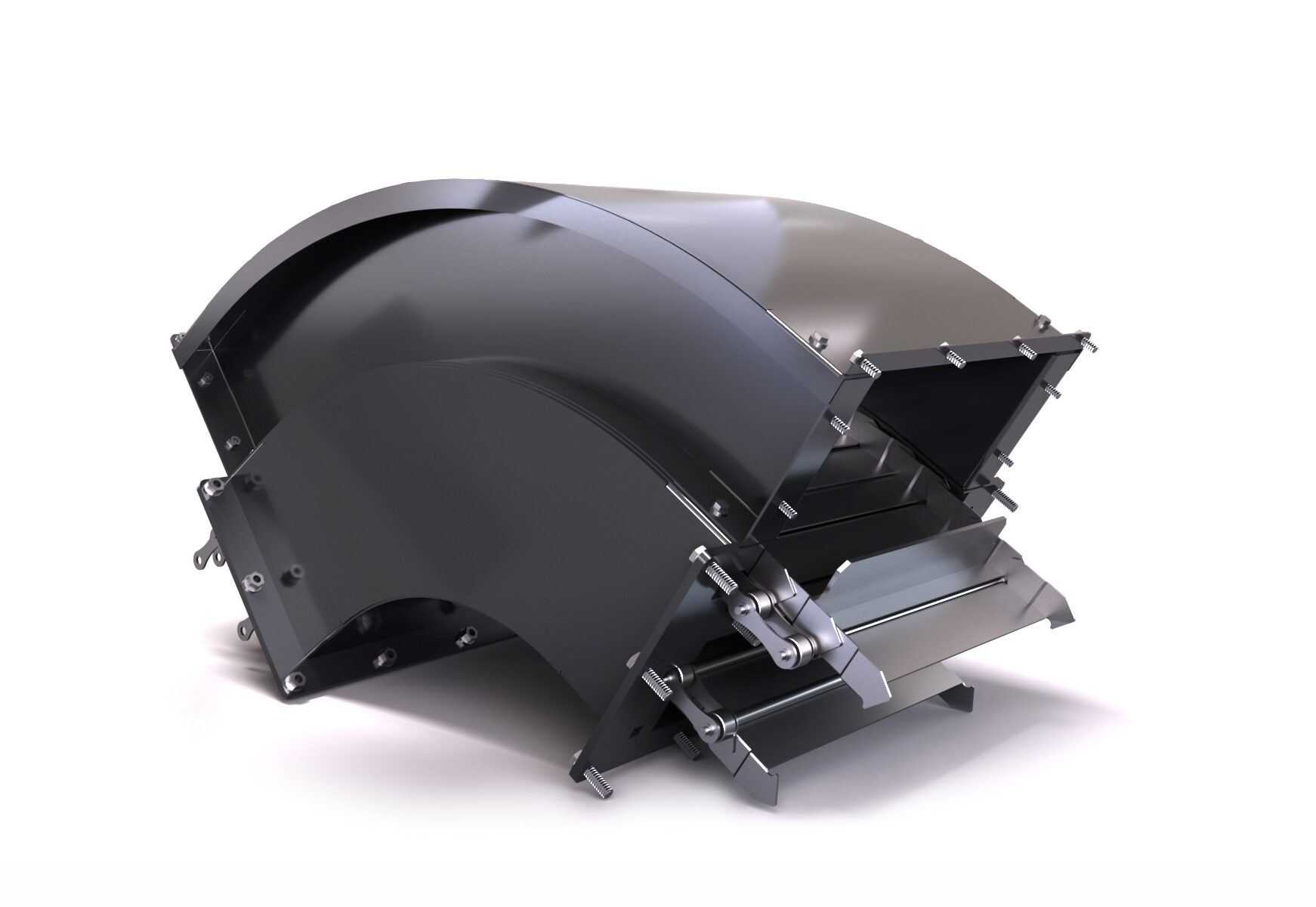

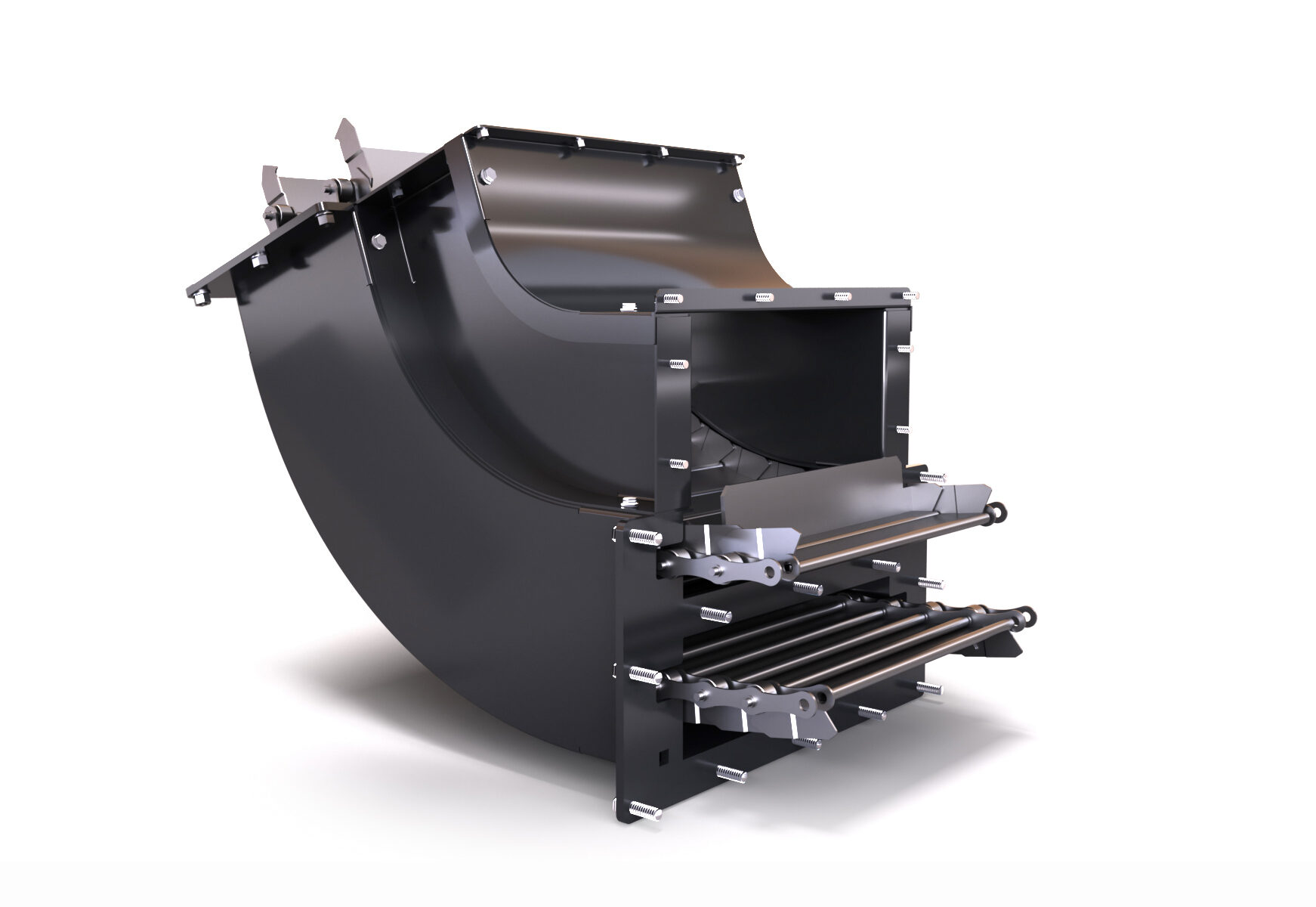

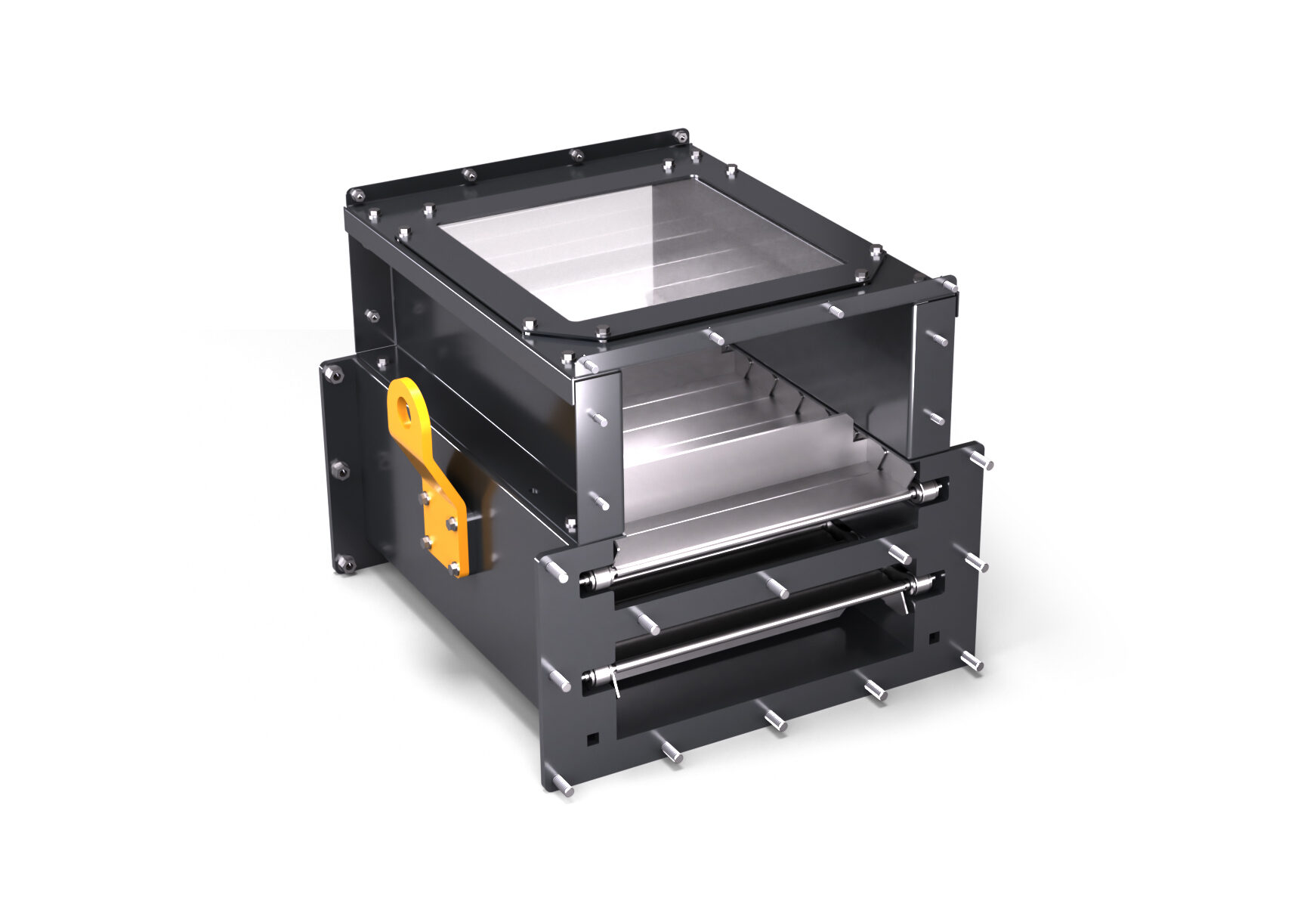

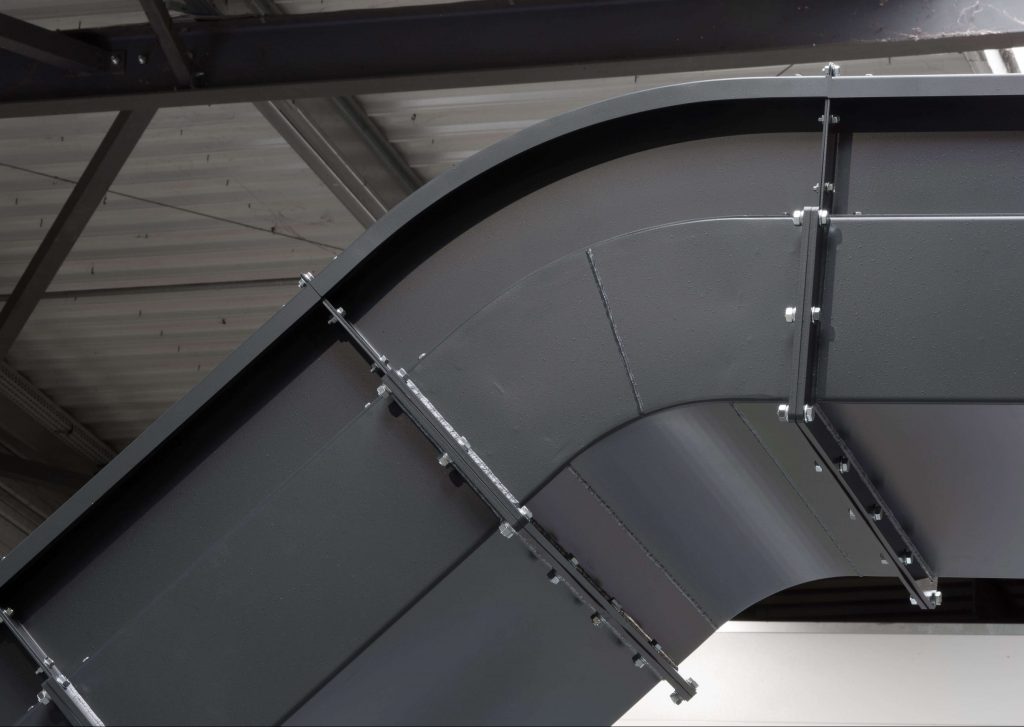

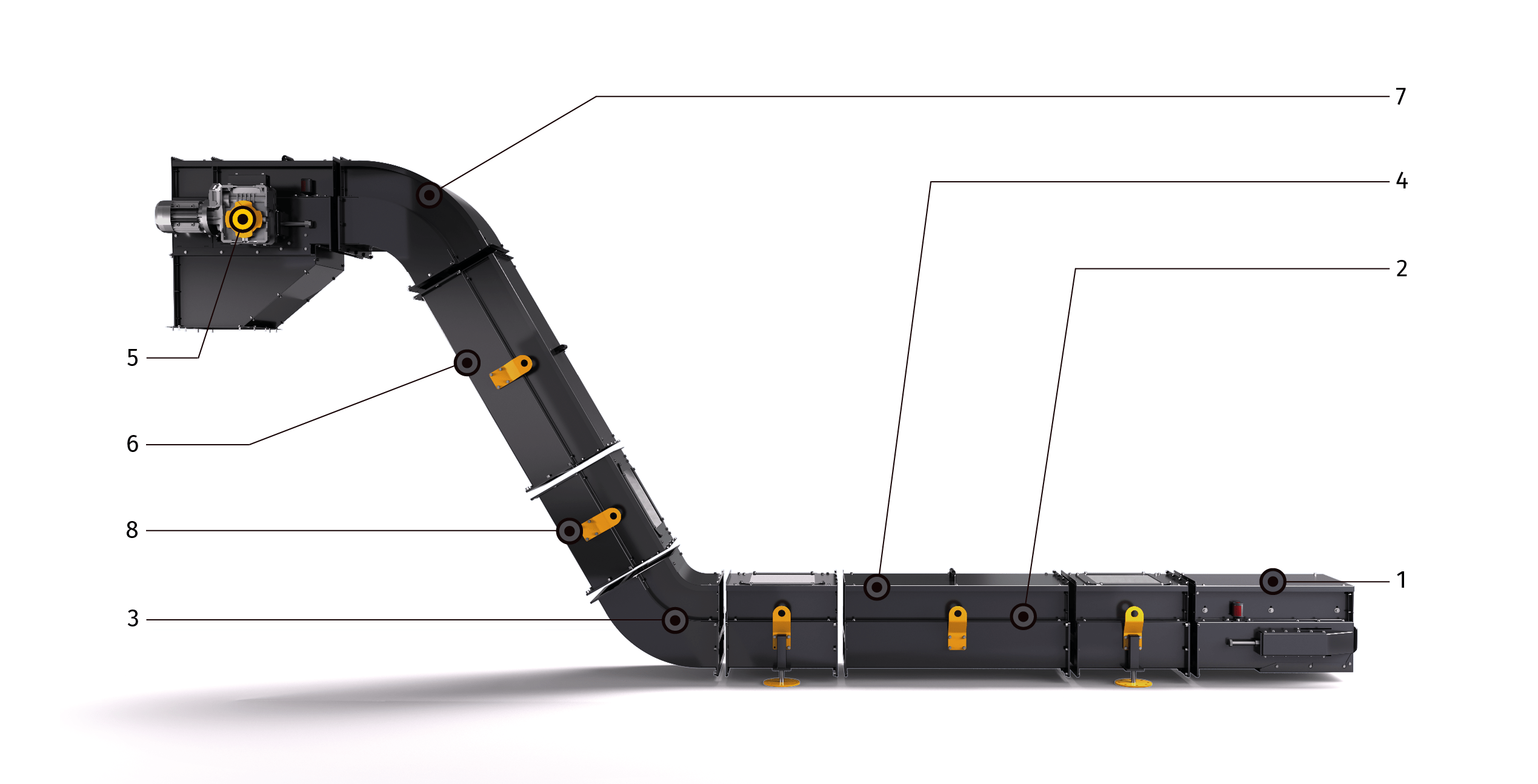

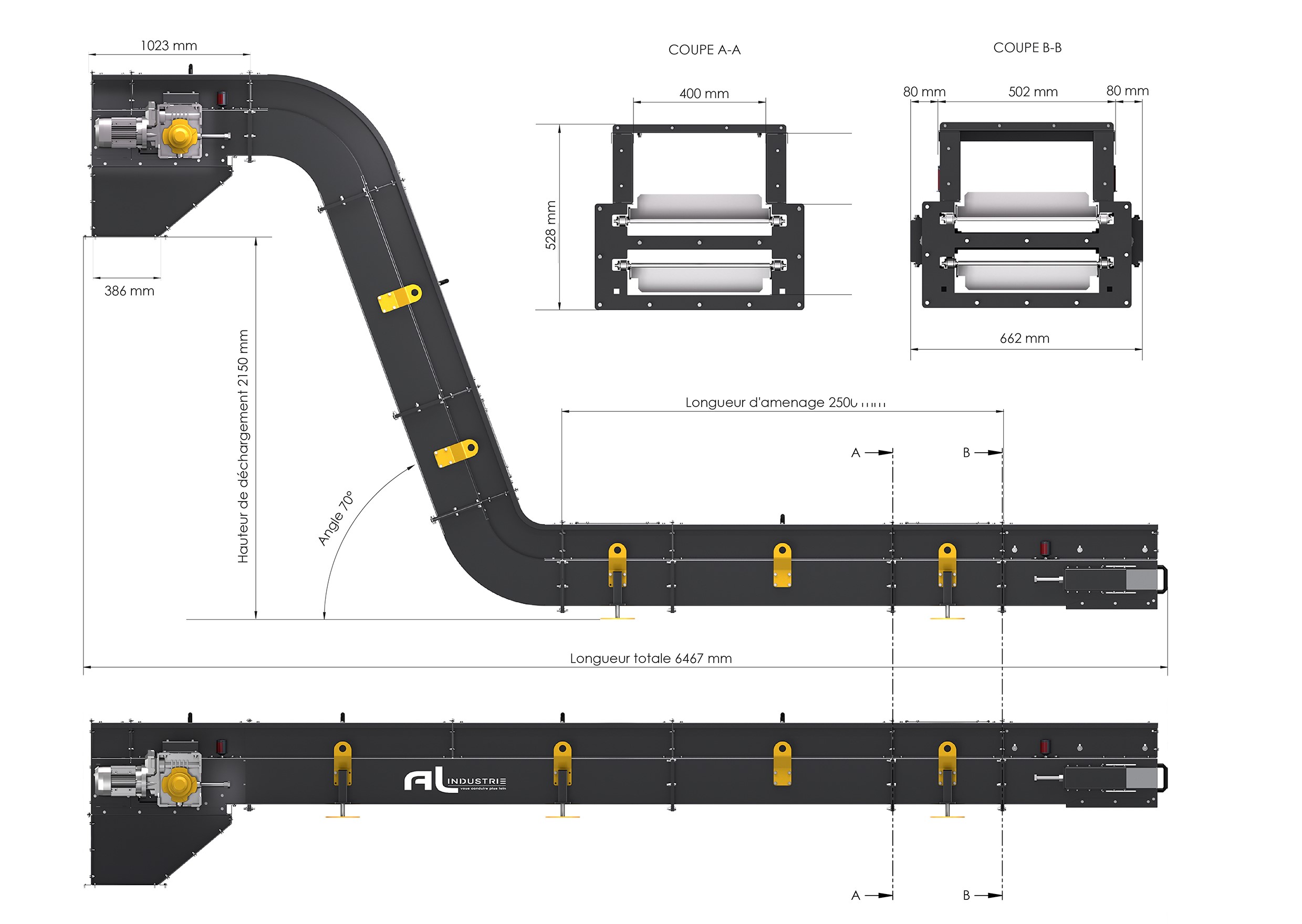

This complete system of T400 module conveyors has been designed to transport up to 10 m3/h of biomass. Modular belt conveyors are made up of rear, straight, curved, head and foot modules. You can choose your tailor-made lifting angle: 0 - 30 - 45 - 60 - 70 degrees, in order to meet all of your biomass projects.

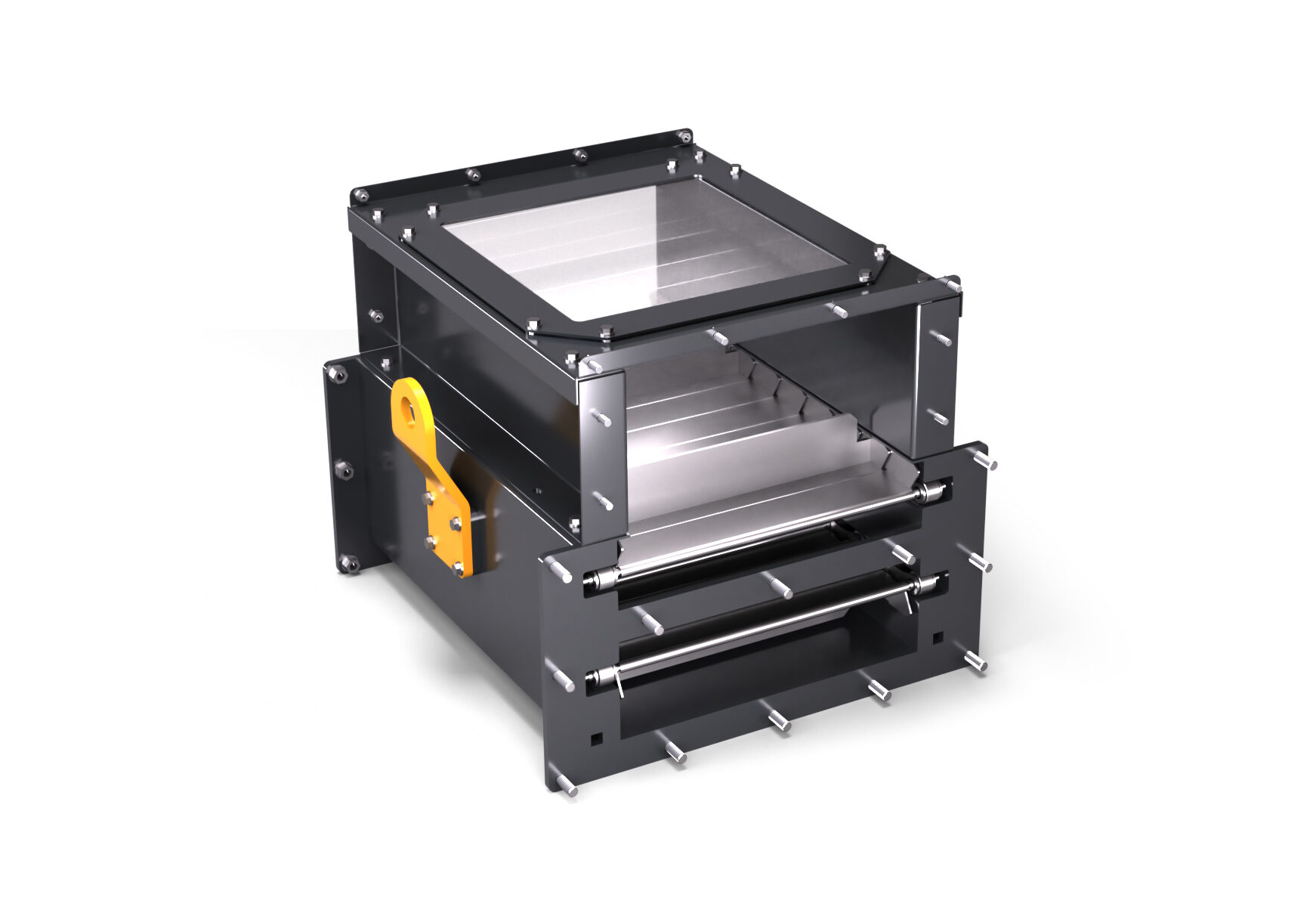

1 - Exclusive structure guaranteed for 10 years.

2 - “Anti-wear” bearing races.

3 - Guide curves machined from the mass.

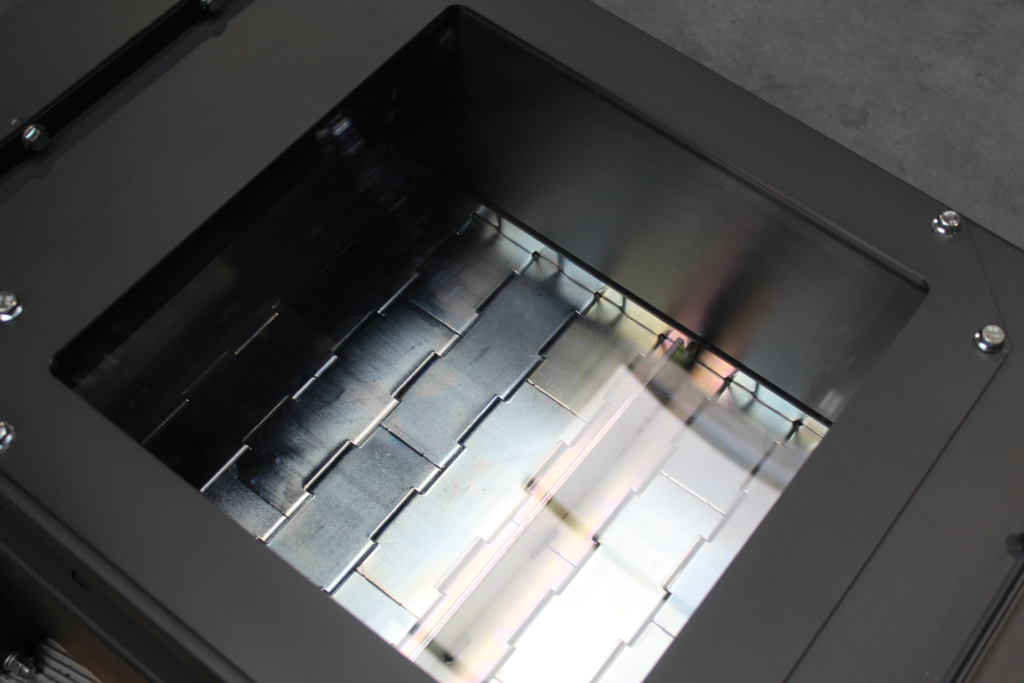

4 - Stainless steel or electro-galvanized belt with high resistance hinges.

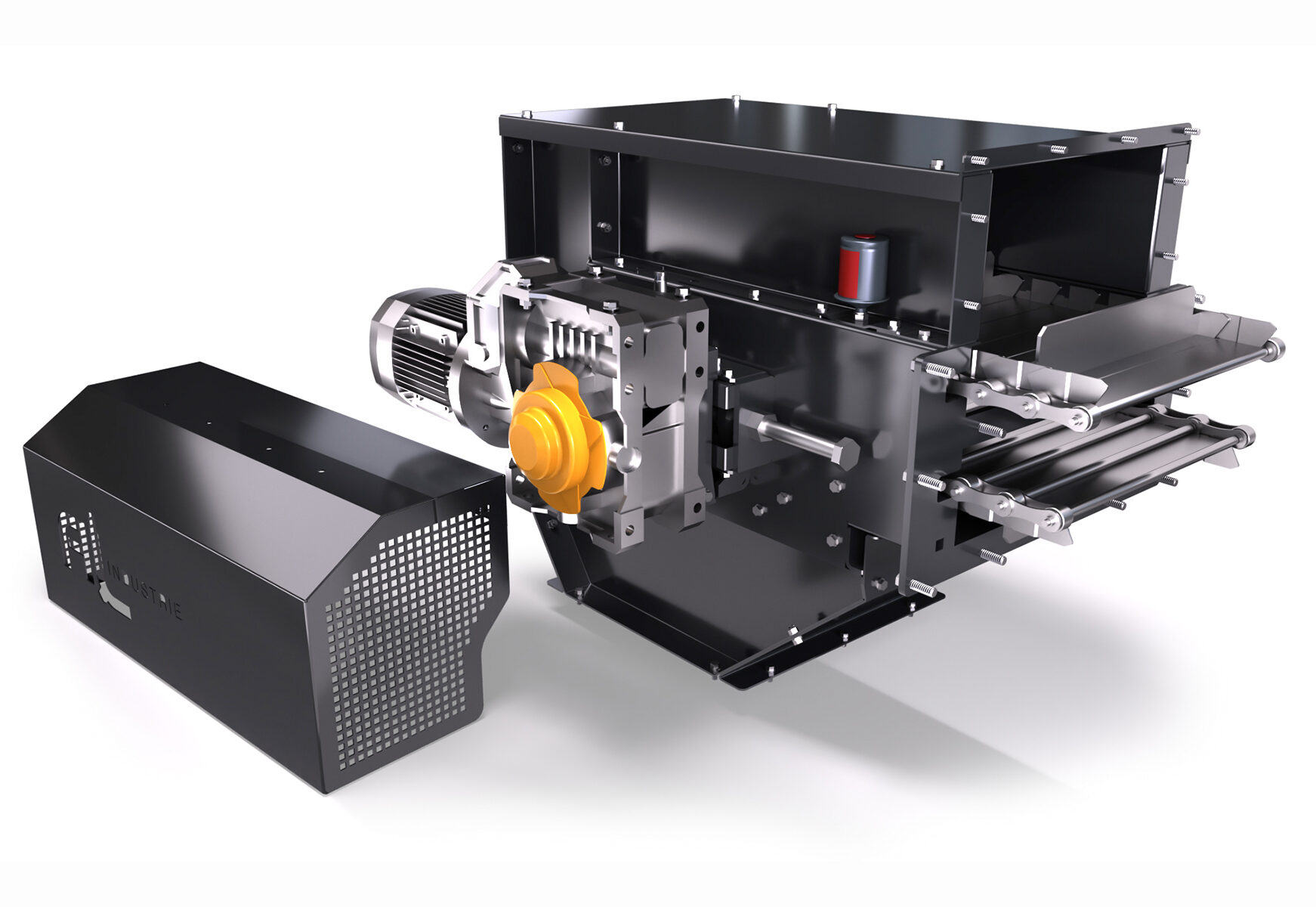

5 - Gear motor with integrated torque limiter.

6 - Patented “anti-return chip” system.

7 - Lift angles: 0 - 30 - 45 - 60 - 70 degrees.

8 - Transport of 10 m3/h.

1 - Exclusive structure guaranteed for 10 years.

2 - “Anti-wear” bearing races.

3 - Guide curves machined from the mass.

4 - Stainless steel or electro-galvanized belt with high resistance hinges.

5 - Gear motor with integrated torque limiter.

6 - Patented “anti-return chip” system.

7 - Lift angles: 0 - 30 - 45 - 60 - 70 degrees.

8 - Transport of 10 m3/h.

A: Feed (mm)

H: Height (mm)

L: Length (mm)

LT: Head (mm)

NW: Width (mm)

a: Angle

On simple request by clicking on the quote request button below, we will send you the address of our automatic conveyor configurator. Don't hesitate, it will allow you to generate your own pdf, dxf and 3D files for your conveyor.

Our projects

20 janvier 2024

Toploader biomass conveyors

7 mars 2024

Biomass conveying dosing hopper

7 mars 2024

Biomass dryer conveyor

17 août 2024

Biomass heating plant in Passy, 74

13 juin 2024

Wood bark conveyor

18 août 2024

Biomass heating plant Prytanée national militaire de La Flèche 72

16 octobre 2024

Groupe SEB's biomass boiler room

28 mars 2025

The IUT of Belfort has equipped itself with the AA-Biomasse Toploader, 100% made in France.

15 novembre 2024

A new Biomasse AA Biomasse toploader installed in Belfort for Tandem Immo!

2 mai 2024